Part 4 – The art & craft of planning your perfect greenhouse

Above: A bespoke Edwardian greenhouse with a feature porch, fitted with cast staging and shelf .

In this final installment of our project planning series, we discuss what many would argue is the only bit that really matters – the growing space inside the greenhouse. It’s possible to spend almost as much on interior fittings and exterior design details as the greenhouse itself, so it is important to consider how you will use the space carefully and what accessories will be essential in optimising the greenhouse as a workspace and maximising your enjoyment of using it. From staging and shelving to lighting and heating, shading and vent controls, read on for inspiration and advice.

Above left: A bespoke freestanding Victorian greenhouse with a partition, cast staging and cast grates set in the floor. Above centre: Keeping the staging to one side in this Arley 7 has left room for a spot to enjoy the vista. Above right: The owners of this bespoke Edwardian mono-pitch lean-to have made use of the back wall, growing a vine and tomatoes straight into the ground and have repurposed some old cast iron legs to add personality to the workspace along the glazed side of the greenhouse.

Staging and shelving

One of the most critical things to get right, nearly all our customers opt for some form of staging and shelving, which is made to suit your greenhouse whether that be one of our Signature buildings or a bespoke design. Our team fit it alongside your greenhouse leaving you ready to start planting. It’s hard to think of many jobs in the greenhouse that won’t benefit from having at least a small amount of workbench height surface, but it does take up space so think carefully before you commit. If you are thinking about leaving room for seating and/or a table, consider sourcing the furniture ahead of the greenhouse and measuring it. Or better still, putting it into what will become your greenhouse once your base is complete but before we come to install, marking out where staging might go with canes to help you envisage how the space is going to work. You are free to make decisions on staging and shelving up to about 2 weeks before we install the greenhouse.

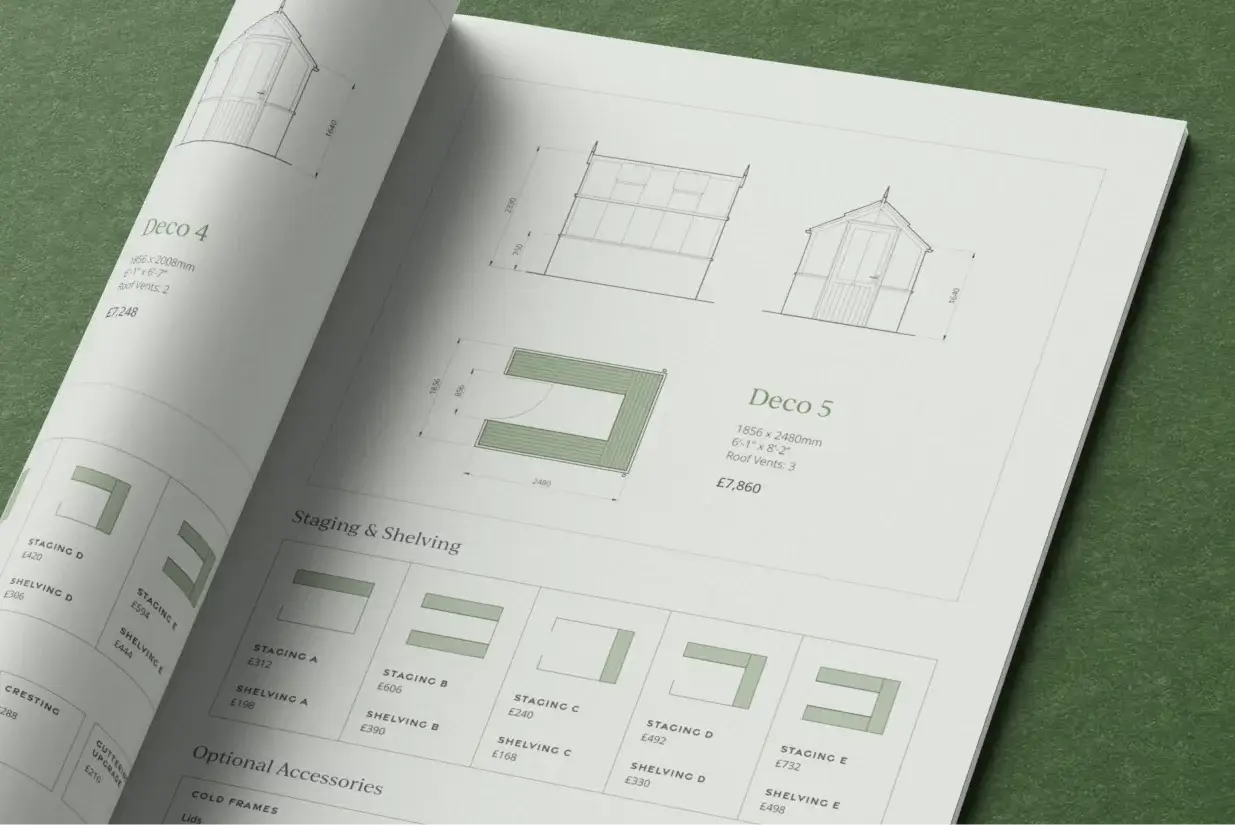

We make our staging and shelving from untreated cedar. Staging is wider, and workbench height and shelving narrower and usually set around shoulder height and is available in a variety of arrangements. For our standard buildings, these are mapped out in the Signature price list and the same terminology can be used to describe the configuration you are interested in for bespoke projects. More complex solutions including multiple tiers and designs that incorporate features such as sinks are also available on request.

And don’t forget the importance of how you finish the floor underneath where you want staging to go. We covered that in more detail in our last edition. You can go back and read that here.

Above left: Staging E and Shelf C in the Deco 6. Above centre: Our Signature Price List maps out the most common arrangements of staging and shelving. Get in touch if you want something different. Above right: Staging D and Shelf A in an Edwardian gable-end lean-to.

Ventilation Control and Vent Opening Gear

All our greenhouses come with automatic roof vent openers. They are made by Bayliss not far from our workshops in Cheshire and we have been using them since our beginning, as many other greenhouse makers have too. It’s a simple, wax-filled piston which expands in the warmth, from about 12°C, to push open the vent, contracting and closing it again as the temperature drops. Robust and uncomplicated, they last for many years beyond their 2-year guarantee and are easily repaired or reconditioned if necessary. And they give peace of mind to the busy gardener. It’s worth noting, however, that they may not be the best choice if you want your greenhouse to be a more multifunctional space that may include furniture and furnishings you don’t want to get wet should it rain at the same time as the temperature rising much above 12°C.

Depending on how much controllability you need, we can offer a range of alternative solutions. For smaller greenhouses where the emphasis is on keeping unpredictable rainfall out, a traditional manual winding system could be the right solution. But for larger greenhouses a motor-controlled system will facilitate all the vents being opened and closed in one motion and more sophisticated climate controls can be integrated.

Above left: Brass manual winding vent opener. Above centre: We use the heavier duty Bayliss Super autovents to open the roof vents on our Victorian greenhouses. Above right: Refurbished and reinstated original cast roof vent controls in a Victorian mono-pitch at Attingham Park, Shropshire.

Side vents are manually operated, as standard. In our Edwardian spec standard buildings (the Deco, Arley and Croft) they are an optional extra so you need to add them if you feel they are necessary for your greenhouse. They usually span single bays and are operated by a solid brass casement stay. We will probably suggest including some if you have a bespoke design. Our Victorian spec, on the other hand, has multi-bay top-hung opening sashes which make it possible to fully open the side of your greenhouse and whilst they, again, have brass casement stays as standard, you also have the option to add traditional cast opening gear. Components are cast from aluminium using existing patterns taken from original ironwork and operate all the sashes (in each section) in one go, from a lever conveniently positioned, avoiding the need to reach through delicate plants.

Above left: Victorian sashes in the Alpine House at RHS Wisley are opened/closed by a motorised rack and pinion system controlled by a computer and sensors that monitor the conditions inside the greenhouse and out. Above centre: single-bay side vents are typical in our Edwardian spec. Above right: Traditional cast vent opening gear is available in our Victorian spec greenhouses. Lever handles can be placed in convenient locations and will operate multiple sashes in one motion.

Heating and Shading

A primary advantage gained by the gardener with a greenhouse is that of the opportunity of a frost-free environment all year round. Where heating is concerned, the majority of our Signature buildings can easily and cost-effectively be kept frost-free with one or two electric fan heaters. We recommend Bio Green, having had plenty of direct experience of their products of the years, but there are other brands out there and deals are to be had if you’re prepared to spend some time trawling the internet.

Fan heaters are a perfectly acceptable solution for many gardeners, but for more delicate growing requirements, a heated pipe system of some description provides a much more beneficial to the plants and reliable to you source of heat. If you’re just looking to extend the growing season i.e. sow seeds a few weeks earlier than the weather might otherwise safely permit, then you should find fans a perfectly sufficient and reliable method. But it’s worth considering investing in a more expensive electric finned tube heating system if plant loss would be costly if temperatures weren’t maintained, and particularly as weather becomes increasingly extreme and unpredictable. Additionally, this type of heater gives off a less drying heat and can be controlled by a more sophisticated sensor. They are hardwired into fused spurs though, so you’ll need an electrician to install them along with the necessary controls.

Where heating is concerned, it’s a good rule of thumb to allow yourself some headroom in the specification you go for against the conditions you are targeting. In other words, it’s better to have more powerful heaters running at a low ebb than the smallest heater having to work at maximum output for much of the time.

Above left: a fan heater is an adequate and cost-effective heating solution for most small and medium sized greenhouses and can be suspended from the roof or stood on the floor. Above centre: electric finned tube heaters are a step up in terms of cost but deliver a more beneficial and reliable heat and can be wall mounted or set in a trench in the floor (above right).

Many of the experts we’ve worked with cite ventilation and plant hydration above shading when it comes to maintaining the best growing conditions for your plants, but it’s another thing we get asked about on a regular basis, so here’s our take: Shading can help lower the temperature inside the greenhouse, protect plants from leaf scorch and make it a bit more bearable for the gardener on those very hot summer days. But, whilst it does this, it blocks out the much-needed light so, ideally, you’ll avoid using it where you can.

Most off-the-peg shading solutions are internal and rely on the standard measurements that the mass producers use which is unhelpful to the vast majority of our customers. As they are on the inside of the glass, they don’t reduce the solar gain from the sunlight coming through the glass nearly as effectively as external blinds, but they may slow heat loss during the night. They can also be flimsy, fiddly to operate and a dust and detritus trap. And once plants such as tomatoes and cucumbers advance, the shades can be impossible to access and operate anyway.

A more effective option in terms of helping to reduce internal temperatures is external shading. Again there are options, but to maintain a traditional appearance, we offer cedar-lath shades which are hand-built using traditional methods and custom-made to suit your individual greenhouse.

Above: External cedar-lath shading fitted to a bespoke Edwardian three-quarter span greenhouse. Designed to fit around the dormer porch roof and under the roof vents.

Lighting

There are several aspects to lighting a greenhouse. The practical – extending gardening time as much as possible, the horticultural – using UV and heat lamps to promote germination and growth, and the decorative – making your greenhouse an enticing focal point and even the ultimate entertainment destination in your garden long after the sun has set.

Our lighting system has a suitably period, industrial feel to it, being inspired by the workshop and factory lighting illuminating industry from the cotton mills of Manchester, the foundries of Birmingham, and the potters of Stoke, from the 1930’s onward. Prior to this, our Victorian and Edwardian forebears would have been relying on oil or gas and whilst we don’t doubt the earliest, more extravagant glasshouses would have been equipped with some form of illumination, this wouldn’t have been a feasible option for the more modest greenhouse gardeners that came on their heels and it was a solution for all that we were keen to offer.

The whole point of our system is that it is carefully integrated into the greenhouse so as to keep the wiring as unobtrusive as possible. It particularly comes into it’s own when you wish to suspend lights from the ridge when the waterproof rating of the light fitting is a key consideration. Remember, any lights suspended from the ridge are in a vulnerable position should it start raining whilst the roof vents are open. Our brass lamp holder (the bit you screw the light bulb into) is IP65 rated – IP stands for Ingress Protection and the grading indicates how well an electrical device withstands the harmful ingress of dust or liquid. The first numeral refers to the protection against solids (such as dust or dirt) and is rated on a scale from 0 (no protection) to 6 (no ingress of dust). The second numeral rates the device’s protection against liquids and uses a scale from 0 (no protection) to 9 (high-pressure hot water from different angles). In other words, IP65 is pretty good.

The shade is a spun metal which we then powder coat in a colour to match your greenhouse. We leave you with a 2700k (warm white) LED light bulb when we fit this system alongside your greenhouse but you are, of course, free to change this to something brighter or more daylight orientated if you wish. We also supply a narrow IP rated switch which can be mounted on the greenhouse framework, by the door for example, but you could have your electrician fit a dimmer switch if the objective is more about creating a mood.

We covered some of the practical aspects of getting power to your greenhouse in Part 3 of this series and reiterate you will need a qualified electrician to do all the wiring and connect everything up.

Above left: Our IP65 rated pendant light is suspended from a colour-matched cable channel which runs underneath the ridge of the greenhouse. The well glass cover (above centre) protects the bulb from moisure ingress. Above right: lighting your greenhouse can add to the overall ambience of your garden and makes an inviting focal point, even in the winter months.

Finishing Details

There’s a couple of final accessories we offer which can be added to complete your growing space with the same polish and attention to detail as the rest of the greenhouse.

A major step up from bits of string and a few granny knots, our discreet stainless steel vine wires can be fitted into the roofs of our greenhouses to provide support for climbing plants, where they, in turn, provide natural shade for other plants. In our Victorian models this includes pre-drilling holes through the large timber portal rafters at the manufacturing stage, to allow the stainless steel ropes to pass through and be secured at the ends of the greenhouse, tensioned with turnbuckles. Components that form part of the roof structure are coated alongside the rest of the greenhouse for a uniform finish, and our team fit the vine wires when they install the greenhouse, leaving you with nothing left to do other than start growing. Talk to us about your growing plans and we’ll work out the details.

We can also make window boards to suit your greenhouse – a timber, typically, bull nosed board which sits on top of the base wall, abutting the inside face of the greenhouse framework and available in untreated cedar to match staging, or painted Accoya to match the framework. It’s a finish that some people choose for aesthetic reasons but it’s also a useful tactic if the top of your base walls are not in ideal condition or visually appealing.

Above left: The fixing points for our stainless steel vine wires are coated alongside the rest of the greenhouse for a seamless finish. Passing through the rafters in our Victorian buildings (above centre), they are sturdy enough to support a bountiful crop without sagging. Above right: A painted Accoya window board is the final flourish in this Victorian greenhouse complete with traditional cast sash opening gear.

We hope this series has provided both inspiration and useful insight for your greenhouse project. We are only skimming the surface, however, and encourage you to get in touch to discuss your own ideas in more detail.

Comments

This article doesn't have any comments yet.