Part 1 – The art & craft of planning your perfect greenhouse

Above: A truly bespoke Edwardian three-quarter span greenhouse with protruding porch, cold frames, multi-bay roof and side vents and a host of other customised features.

Not sure where to start planning your perfect greenhouse? Read on as we share our in-depth knowledge, gathered over many years of making traditional greenhouses and bringing gardeners aspirations to life.

Faced with a myriad of greenhouse makers and an array of materials, methods, design credentials, functional criteria and price points, it can take time simply researching the market, understanding what’s on offer and establishing a shortlist of companies who you think might be a good fit for you.

With potential costs varying considerably, it’s important to understand what you are getting for your money, especially if you are considering investing in something you hope will bring you many years of joy. A simple poly tunnel, for example, is an extremely cost-effective way of extending your growing season and providing the plant protection that a greenhouse is primarily for and many a successful gardener champions them. But an attractive feature they are not! We recommend drawing up a list of your key criteria, much like you would if you were house hunting.

Key areas to think about:

Design

Materials

Location

Maintenance

Lifespan

Above: The Arley 10 finished in Pebble Grey sits comfortably in this naturalistic Sussex garden

Design

One of the things you get when you start to move up the cost ladder is improved design. This might mean more authentic attention to detail where period features and proportions are concerned. Or it might mean the functionality of the greenhouse is better thought through, so the space is easier and more enjoyable to work in. It can also mean a more design orientated team to help you along the way to visualising your dreams.

The term “Victorian Greenhouse” is widely used to describe a more traditional style of greenhouse and there are lots of companies using this vernacular as a general way of segmenting their product ranges which will also include more contemporary designs. Here at White Cottage, however, we use the term to specifically describe one of the two specifications that we offer (Edwardian being the alternative), inspired by the distinct design aesthetics of those periods and how glasshouse manufacture and usage evolved allowing growing under glass to go from a preserve of the affluent to a possibility for everyone. You can read more about our specifications and the key differences between them here and look out for a future journal entry which will explore this further.

Wherever you live, be it a period property, a rural cottage or a contemporary urban new-build, a well-considered, timeless design will continue to feel right for many years to come.

Left: A custom colour on this Arley 7 resonates with the Lincolnshire limestone of the area. Right: Black was chosen by the owners of this Croft 2 to fit in with the contemporary extension to their Victorian London home.

A key component of any traditional style greenhouse, and integral to the handwriting of ours, is the low base wall. A design feature first established by the Victorians who pounced on the increasingly available technologies of the time to help them extend the growing season and increase yield to better feed their families and wider communities. These advancements also made it possible to create a climate for experimentation with produce beyond the reach of the British gardener and the glasshouse quickly became an arena for competitive showing off with all manner of vineries, pineries, pit houses, orangeries, ferneries, hot houses and winter gardens displaying increasingly elaborate design aesthetics to house increasingly exotic plant collections.

Putting the pineapples and prostrating to one side, however, the low base wall does have a number of practical advantages, which we feel should not be overlooked, even by the most modest of gardeners. Glass to ground may seem like a good idea – the more glass, the more light, right? But a supporting dwarf wall delivers a lot more advantages over this.

Above: The reinstatement of an original Victorian glasshouse in the Walled Garden at Sandwell Park, West Bromich, perfectly articulates the authenticity of our Victorian specification.

Plants grown in the ground alongside the dwarf wall have their roots shaded from direct sun and the earth is kept cooler and moister for longer. It provides the ideal location for heating pipes or wall-mounted electric heating tubes. You’ll often see apertures built into the dwarf wall of original period glasshouses through which they would draw in the fresh cold air to warm up as it crosses the heating pipes before it distributes throughout the greenhouse. This can also work the other way if you site cold frames on the outside – warmth from the greenhouse trickles through into the cold frames. And don’t forget present day concerns such as where to site sockets, for example, or worries over the potential for broken glass in proximity to pets and young children, with glass-to-ground designs being so much more vulnerable to accidental damage.

In the third instalment of our greenhouse planning series, we’ll cover the base wall in a lot more detail including choice of materials alongside considerations such as how you might use the space, surrounding landscaping and internal flooring.

Left: The original heating pipes run along the interior perimeter of this Victorian mono-pitch lean-to in Shropshire. Right: cold frames are mini extensions to the greenhouse, providing space for hardening off or overwintering.

Materials: Timber or aluminium?

There are strong arguments for both; Aluminium is an abundant and easily recycled material that offers both longevity and low maintenance. Timber, assuming it’s coming from a certified source, can have a lower carbon footprint and is renewable, as well as being the traditional material that many battling listed building constraints may be being encouraged to choose. And it delivers that difficult to put your finger on ambience. It feels different, sounds different, smells different…

Well then, why not have both? Which is our unique position. Don’t be confused by the aluminium capping that some timber greenhouse makers clad to their timber roof structures. This method may offer some extension of lifespan to the roof, but the roof is still ultimately vulnerable to rot. In our greenhouses, all the roof profiles are made of aluminium so they cannot rot, and they don’t require an exterior decorator with Cirque du Soleil experience to repaint them in years to come!

But we can’t get away from that difficult-to-define feeling of being in a timber greenhouse. Our father’s distinct and unfading childhood memory was of his grandfather’s Edwardian greenhouse, made of wood and painted white. Every White Cottage Greenhouse is born from this seed, which is why we continue to make the rest of our buildings in Accoya® wood and paint them. You can read more about why we shifted to Accoya® here.

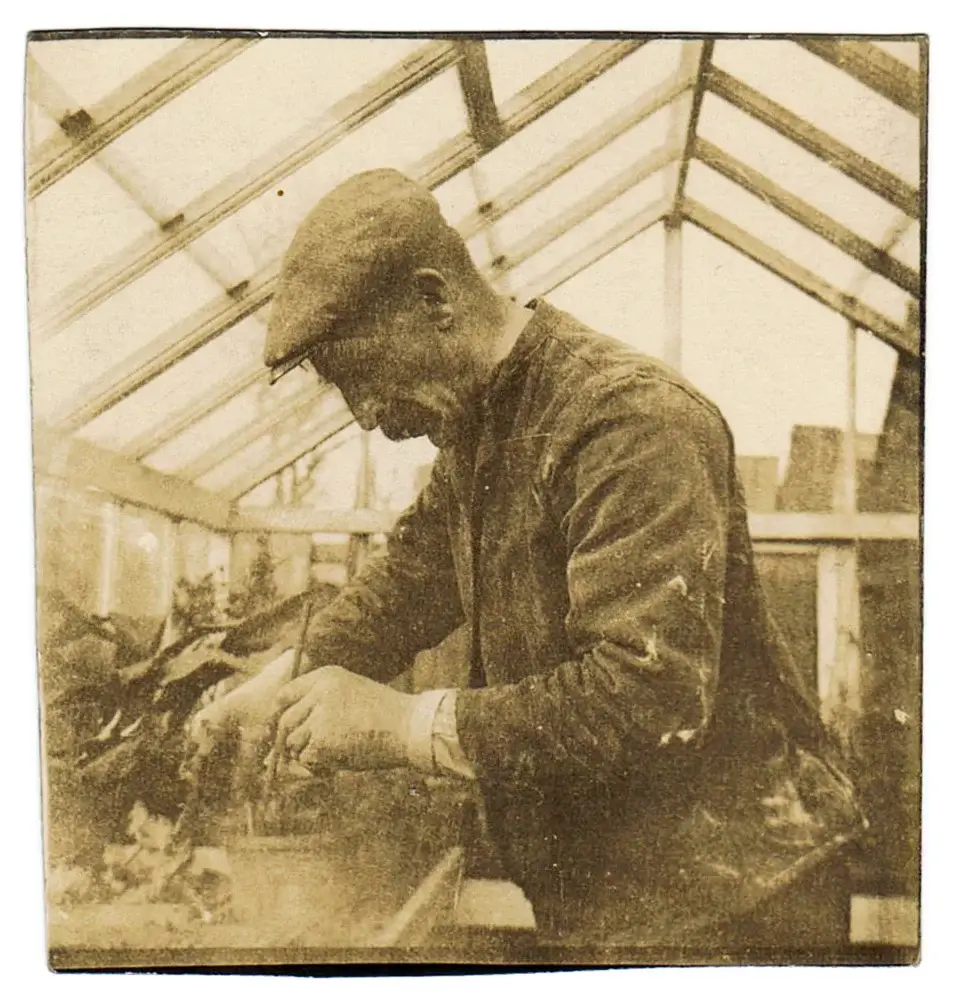

Left: Our great grandfather potting on in his greenhouse in Warrington, circa 1930’s. Centre: The Arley is one of our Edwardian specification standard buildings inspired by our father’s childhood memories of growing veg with his grandfather. Right: We combine traditional joinery methods familiar to our forebears with modern materials selected for their longevity and ease of maintenance.

Alongside deliberating the key structural materials for your greenhouse, don’t overlook all the other components that go into it. Using quality fixings, ironmongery and coatings are equally important and affect your daily enjoyment of the greenhouse, the ease and regularity of maintenance and the overall longevity. Stainless steel fixings and solid brass hinges, door and window furniture are used throughout our buildings with our decorative ironmongery being handcrafted in Birmingham by a brass foundry with a 155-year history (learn more about this family-run business here). The difference between a well made door handle and one that has been engineered and mass-produced for the lowest price is something you’ll become increasingly appreciative of as time goes by. Every time you open or close that door, you’ll experience a brief moment of satisfaction.

We are similarly fastidious about the paint we use too. Manufactured by Finnish innovation and environmental warriors Teknos, it’s a system that has been developed in partnership with Accsys (the producers of Accoya) and now, with decades of testing behind it, is backed up with an up to 12-year warranty (there are some caveats for extremely exposed locations). Read about their sustainability efforts here.

Look out for our upcoming Supplier Spotlight reports where we’ll go in deep with some of the companies we work with who share equally our passions for craftsmanship, longevity and transparency.

Left: Stainless steel fixings are standard in our greenhouses. Centre: A British, handmade, solid brass door handle will serve you well for many years to come. Right: Our paint has been specifically developed to work in harmony with Accoya and delivers the traditional period look with world-class low-maintenance longevity.

In the 2nd instalment of this project planning series we’ll talk about choosing the right location for your greenhouse, how the right type of structure can help you make the most of your chosen site, and how the materials used to make your greenhouse can impact on ease of maintenance and the overall lifespan of it.

Comments

This article doesn't have any comments yet.